Sustainable management

Tapex is always with you.

Environment Policy

Tapex recognizes that proactive responses to environmental changes and the safety and health of workers are key elements of sustainable management. Based on this, we have established and run a company-wide environmental management system that can proactively take preventive actions for environmental issues and environmental management activities, and create a safe working environment by thoroughly controlling safety accidents and health risks.

Environmental and health & safety management system in operation

In order to systematically implement environmental and health & safety management, we have obtained the international standard of environmental and health & safety management system (ISO 14001, ISO 45001) certification. Based on these systems, we improved the risk factors within our premises to prevent environmental and safety incidents, and strengthen the health of our executives and employees.

Environmental and health & safety management system certificate

| Categories | ISO 14001 (Environmental Management System) | ISO 45001 (Occupational Health and Safety Management System) |

|---|---|---|

| Yanggam Factory | 2020. 05. 07 ~ 2023. 05. 06 | 2020. 05. 07 ~ 2023. 05. 06 |

| Paltan Factory | 2021. 09. 13 ~ 2024. 09. 13 | 2020. 08. 14 ~ 2023. 08. 13 |

| Hyangnam Factory | 2022. 07. 11 ~ 2025. 07. 10 | - |

Emergency response and preparedness training

We have established an emergency plan to respond to fire, explosion, or leakage promptly and systematically, and are working on minimizing the damage with regular emergency response drill.

-

Joint public training

-

Fire suppression training

-

Leakage Prevention Drill

Safety Campaign for Incident Prevention

In order to raise the safety awareness of our employees, we continue to carry out safety campaigns to chant safety slogans, and post safety signs and banners for observing safety rules and wearing protective gear.

Safety Campaign Activities

Environmental safety patrols and regular meetings

We carry out periodic environmental safety patrols and hold regular environmental safety meetings to realize a zero-accident workplace by discovering and improving potential harmful and dangerous factors.

| Categories | Operation type | Operation monitoring |

|---|---|---|

| Environmental safety patrol | Self-inspection | monthly basis |

| Cross check | quarterly basis | |

| Environmental safety regular meeting | face-to-face meeting | quarterly basis |

Process Safety Management

Through the implementation of 12 principles in accordance with the systematic process safety management system, we are strengthening the prevention of serious industrial incidents such as fire, explosion, and leakage of hazardous substances.

Antismoking campaign and reward system for those who stop smoking

To promote the health of our employees, we are continuously running a antismoking campaign, and have been operating a reward system for the employees who successfully stop smoking since 2015. Through this system, many executives and employees succeeded in quitting smoking, and received bounties throughout two rounds. In addition, we plan to expand the various systems for the health of our employees in the future.

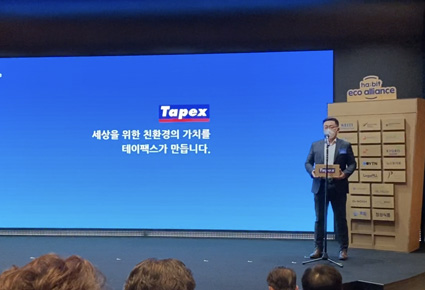

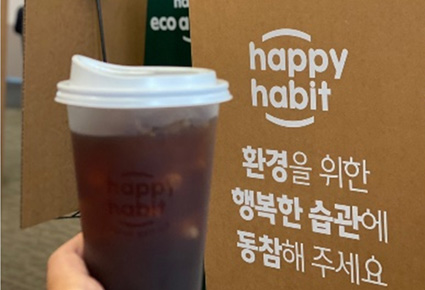

Finalized Agreement of 'Habit Eco Alliance'

The 'Habit Eco Alliance' is a public-private association that was organized to lead the reduction of disposable cup usage under the slogan of “happy habit”. Tapex officially signed the agreement in November 2021 and is playing a key role as a product supplier in the multi-use cup business that replaces disposable cups.

Environmental safety education for executives and employees

In accordance with the annual training plan, systematic environmental health and safety education is regularly conducted for out executives and employees. In addition to the legally compulsory education for the person in charge of environment, health & safety, its practitioners, and hazardous chemical handlers, we prevent any incidents and raise our employees’ awareness on environment and health & safety management by expanding various educations and briefing sessions related to environmental and health & safety issues.

| Title of Training | Teaching method | Training hours | Training period | Subject | Number of trainees |

|---|---|---|---|---|---|

| Environmental technician (air, waste, noise and vibration) training | Collective + Online Training | 9hr | June to October | Hands-on worker | 4 people |

| Chemical management | Collective | 16hr | April | Person in charge | 1 person |

| Hazardous chemical substance (supervisor, handler) education | Collective + Online Training | 16hr | Always | Supervisor/handler | 85 people |

| Candidate Training for Hazardous chemical manager | Collective | 32hr | December | Supervisor | 1 person |

| Hazardous Chemical Substances (Persons Working) Education | Online | 2hr | Always | Persons Working | 195 people |

| Regular safety and health education | Collective | 24hr | January to December | All employees | 322 people |

| Supervisor training | Collective | 16hr | Always | (Assistant) Foreman | 36 people |

| Process safety management training | Collective | 2hr | June to October | Hands-on worker | 29 people |

| Training for professional forklift operator | Online | 2hr | January to June | Hands-on worker | 28 people |

| Carbon neutral education | Online | 2hr | October | Supervisor | 1 person |

| Briefing session on the SERIOUS ACCIDENTS PUNISHMENT ACT | Online | 8hr | February, December | Supervisor | 5 people |

| Environmental Management Course | Collective | 16hr | March | Supervisor | 1 person |

| Seminar on Response to the Serious Accident Punishment Act | Online | 5hr | May, July, November | Supervisor | 1 person |